Learn more about your tyres

About Tyres

Zenises understands that whilst tyres may be regarded as ‘black and round’ by many drivers, they are actually a remarkable piece of automotive engineering. But rather than bamboozle you with technical data, we’ve put together a simple guide to help you with your tyre’s performance and general care and maintenance – and therefore to help with the driving experience.

You should always remember that your tyres are the only point of contact your vehicle has with the road so you can appreciate why it is important that you select the right tyre type for the vehicle you are driving and for the purpose it is being used. It’s also the law which requires your vehicle to be fitted with the correct type and size of tyre. Moreover, it’s a good habit to regularly check all four tyres for pressure and general wear and tear – and don’t forget to check the spare tyre too.

Probably the most important advice with regard to tyre care of these is to check the tyre’s minimum tread depth. The legal limit for minimum depth of the tread on your tyres is 1.6 millimetres, across the central ¾ of the tread going around the complete circumference of the tyre.

- Read on to find out more about your tyres and how to understand and care for them properly.

-

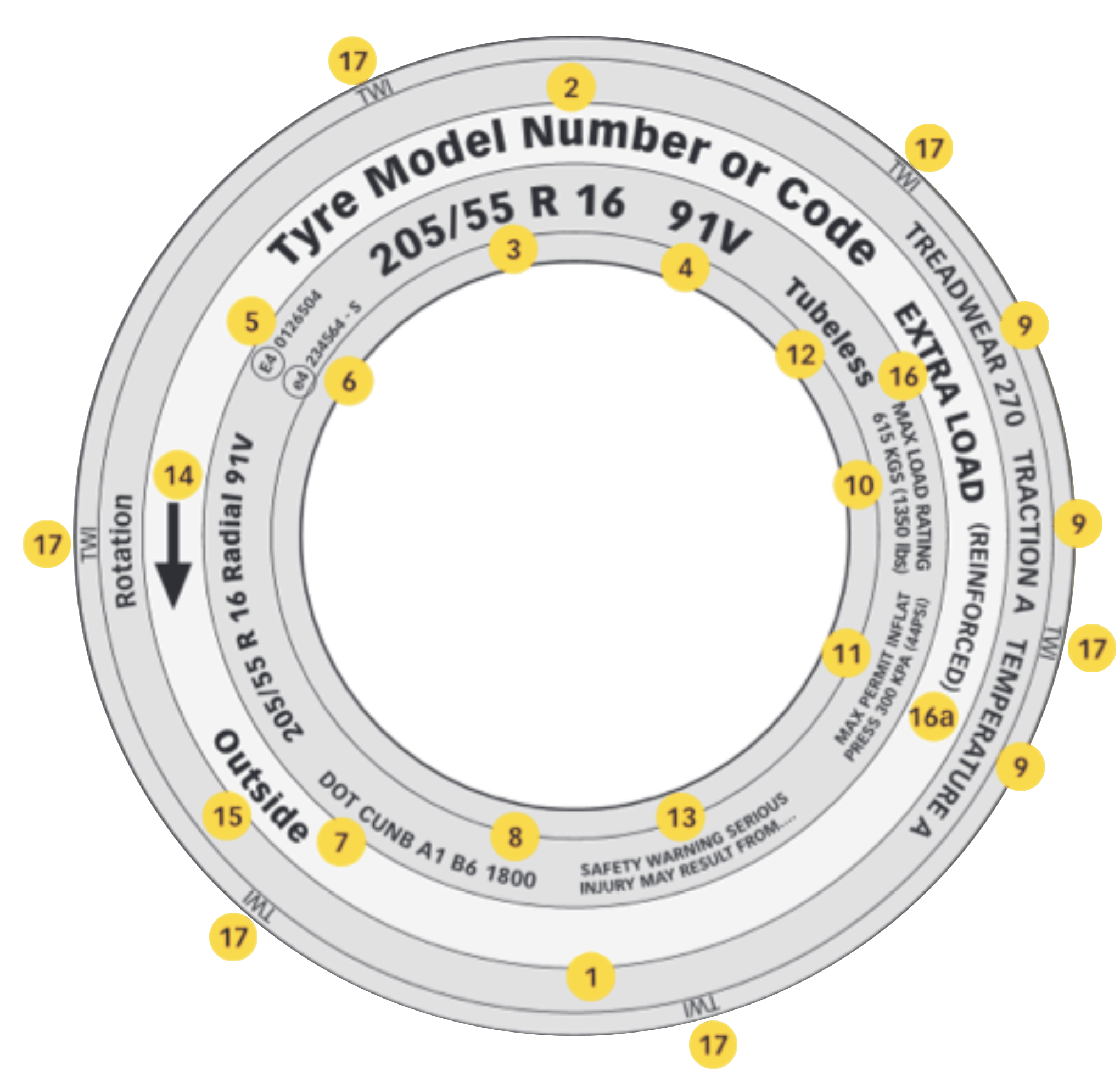

Getting to know your tyre better

1) Manufacturer’s name or brand name

2) The manufacturer’s model or pattern code

3) Tyre size, nominal section width (expressed in mm e.g. 205), height to width aspect ratio (height of the tyre’s sidewall as a percentage of the width, e.g. 55% or 55); and the rim diameter code (the diameter of the tyre’s central ‘hole’ in inches e.g. 16″. The letter between the numbers is the type of construction, usually ‘R’ for ‘Radial’. For example 205/55R16.

4) Service descriptions (Load Index + Speed Symbol). In the diagram the figure 91 denotes the maximum weight capacity of the tyre according to the official load index table, which translates to

615 Kg, The letter V indicates the speed rating of the tyre, in this case the tyre suitable for cars capable of reaching a maximum vehicle speed of 240 km per hour.

5) ECE (Economic Commission for Europe) Regulation 30 Conformity Approval Number – this means that the tyre meets the standards of the European regulatory authorities.

6) EEC Noise Approval Number – this means that the noise generated by the tyre is within approved European limits.

7) USA Dept of Transport Manufacturer’s code – often referred to as DOT number which has no significance in Europe

8) Date of Manufacture – a very important code as the age of a tyre can affect its performance. The first two numbers refer to the week of production (e.g. 18 = week 18) and the third and fouth numbers refer to the year of manufacture (e.g. 00 = 2000, 15 = 2015)

9) USA UTQG Quality Grades – no significance in Europe

10) USA Maximum Tyre Loading – no significance in Europe

11) USA Maximum Tyre Inflation Pressure – no significance in Europe

12) Denotes ‘Tubeless’ construction type

13) Safety Warning – refers to the dangers of under-inflation/overloading and the mounting of tyres together with the risk of severe over-inflation.

14) Direction of Rotation – with relevance to directional pattern tyres only

15) Outer (Inner) sidewall – refers to asymmetric pattern tyres only. These tyres have different tread patterns on their inner and outer sides, offering improved performance, and must be fitted correctly.

16) Extra Load – denotes that it has a higher load capacity than a standard load tyre. “Reinforced” is sometimes used as an alternative marking to “Extra Load”

17) TWI-tread wear indicators- raised areas at the base of the tread grooves to serve as a visual warning of when the tyre is approaching or at the minimum legal limit.

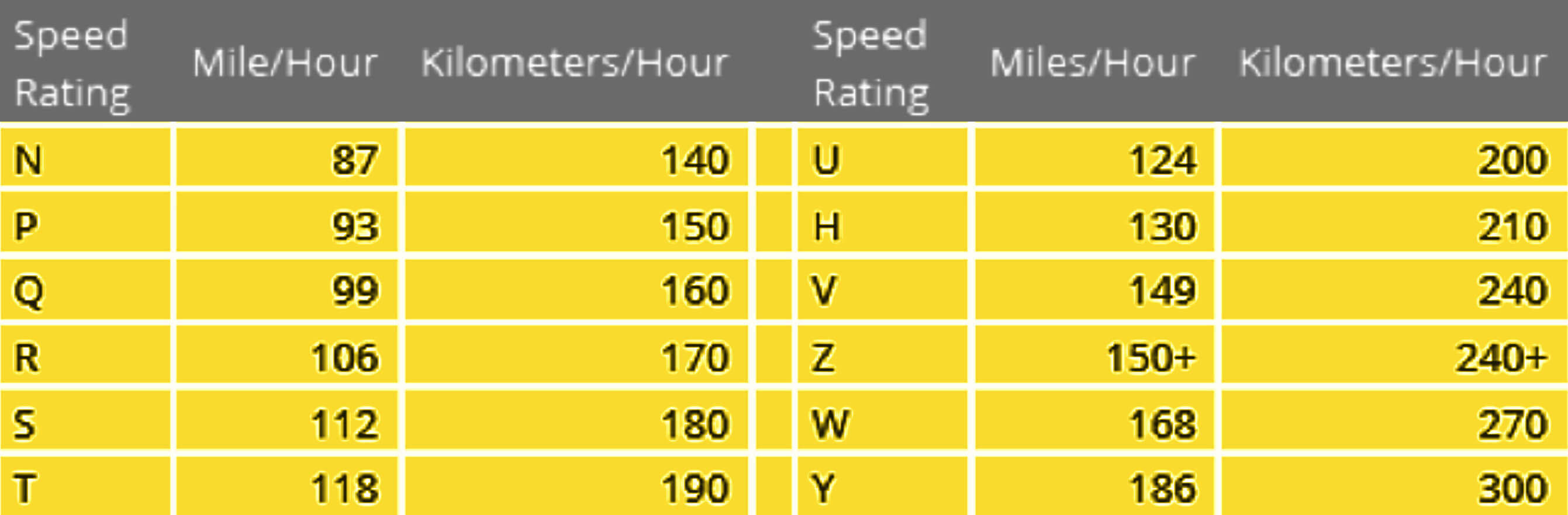

Tyre speed rating

All tyres are marked with a speed rating letter that corresponds to the maximum speed a vehicle can travel under conditions specified by the tyre manufacturer. These speed indexes are calculated when tyres are in a new condition. So these ratings do not apply to tyres which are damaged, under or overinflated, overloaded or repaired. And remember, just because you may have tyres which can perform at high speeds, no manufacturer would recommend driving above the legal speed limit.

The speed rating of a tyre is represented by a letter on the sidewall. For example, the “T” rating in the table below, tells us that this tyre can reach speeds of up to 190 kilometres per hour or 118mph. So when you know your tyre speed rating, you can calculate what is the maximum speed your tyre is capable of running.

- Read on . . .

- Speed ratings are based on tests in which tyre engineers run the tyre at increasing speed increments, every 10 minutes, until the particular speed rating has been met.

Tyre load rating

The load index is a numerical code corresponding to the maximum load a tyre can carry at a speed indicated by its speed symbol under service conditions specified by the tyre manufacturer.

- Read on . . .

- The following table shows what the weight that each index specification is able to carry:

Load index weight each tyre [kg] 19 77,5 20 80 21 82,5 22 85 23 87,5 24 90 25 92,5 26 95 27 97,5 28 100 29 103 30 106 31 109 32 112 33 115 34 118 35 121 36 125 37 128 38 132 39 136 40 140 41 145 42 150 43 155 44 160 45 165 46 170 47 175 48 180 49 185 50 190 51 195 52 200 53 206 54 212 55 218 56 224 57 230 58 236 59 243 60 250 61 257 62 265 63 272 64 280 65 290 Load index weight each tyre [kg] 66 300 67 307 68 315 69 325 70 335 71 345 72 355 73 365 74 375 75 387 76 400 77 412 78 425 79 437 80 450 81 462 82 475 83 487 84 500 85 515 86 530 87 545 88 560 89 580 90 600 91 615 92 630 93 650 94 670 95 690 96 710 97 730 98 750 99 775 100 800 101 825 102 850 103 875 104 900 105 925 106 950 107 975 108 1000 109 1030 110 1060 111 1090 112 1120 Load index weight each tyre [kg] 113 1150 114 1180 115 1215 116 1250 117 1285 118 1320 119 1360 120 1400 121 1450 122 1500 123 1550 124 1600 125 1650 126 1700 127 1750 128 1800 129 1850 130 1900 131 1950 132 2000 133 2060 134 2120 135 2180 136 2240 137 2300 138 2360 139 2430 140 2500 141 2575 142 2650 143 2725 144 2800 145 2900 146 3000 147 3075 148 3150 149 3250 150 3350 151 3450 152 3550 153 3650 154 3750 155 3875 156 4000 157 4125 158 4250 159 4375 Load index weight each tyre [kg] 160 4500 161 4625 162 4750 163 4875 164 5000 165 5150 166 5300 167 5450 168 5600 169 5850 170 6000 171 6150 172 6300 173 6500 174 6700 175 6900 176 7100 177 7300 178 7500 179 7750 180 8000 181 8250 182 8500 183 8750 184 9000 185 9250 186 9500 187 9750 188 10000 189 10300 190 10600 191 10900 192 11200 193 11500 194 11800 195 12150 196 12500 197 12850 198 13200 199 13600 200 14000 201 14500 202 15000 203 15550 204 16000

Tyre Types

Radial ply tyres are now the most common tyres in use on European roads representing well over 90% of all tyres fitted today. Some radial ply tyres now have a run flat capability known as Self Supporting Run Flat (SST) tyres which are becoming more common as these tyres are now fitted as original equipment on many vehicles.

Older cross-ply (or diagonal) tyres are now very rarely seen and have effectively been replaced by radial ply tyres. Cross-ply construction tyres are more common on ‘vintage’ or ‘classic’ vehicles.

Radial ply tyres may be either steel or textile braced and are identified in the size marking by the letter “R” and often the word “Radial”.

Self Supporting Run Flat (SST) tyres are designed to provide a limited driving run on period following a puncture. These are identified by the letters “RF” in the size marking. To be categorised as a run flat tyre, the minimum distance they must achieve in a run flat condition is 80 km (50 miles) at a maximum speed of 80 km/h (50 mph) and at a minimum of 80% of their maximum load capacity.

It is essential the vehicle is equipped with a tyre pressure monitoring system to enable use of run flat tyres.

Tyre Patterns

a) Non-Directional Tyres

The most common tyre pattern type is the non-directional pattern which has no special requirement with regard to orientation and position when fitting on to the vehicle. The tyre performance is not dependent on the direction of rotation.

b) Directional Tyres

A trend originally seen with the growth of high performance cars is the directional pattern which intends to provide better straight line stability. These patterns must be fitted the correct way round on the wheel and also the position on the vehicle to ensure the correct direction of rotation is achieved.

c) Asymmetric Tyres

As car performance improves, tyre design must keep pace and asymmetric patterns are becoming more common, especially on modern ‘performance’ cars. The pattern is different either side of the centre rib, and is intended to be a better balance between wet and dry handling.

Except in the case of temporary use spare tyres supplied as original equipment, it is dangerous to mix tyres of different types on the same axle. It is also advised that the same tyre type is fitted to all wheel positions.

Keep the pressure correct

Recommended tyre inflation pressures for your vehicle can be found in the vehicle handbook and/or mounted on the vehicle bodywork (for example within the door cavity or inside the fuel cap). Correct pressures are related to loads, speeds and vehicle handling and are vital for maximum safety, braking, grip and good tyre life.

Prolonged under-inflation causes excessive flexing, deterioration of the casing and rapid wear of the tread shoulders. The vehicle will also consume more fuel. Over-inflation results in an uncomfortable ride, a reduced area of contact with the road, accelerated wear on the tread centre and makes the tyre more susceptible to impact damage.

Inflation pressure should be checked at least every two weeks and only when the tyre is cold, since there is an increase in pressure when the tyre has warmed up after being run.

A reliable and accurate pressure gauge should be used.

Tyre inspection and maintenance

Examine your tyres regularly, removing stones and other objects embedded in the tread. If you see the tyre has lumps or bulges it must be examined by a tyre specialist since these could indicate internal damage. Wipe away oil or grease with a suitable diluted detergent.

- Read on . . .

-

Watch your tread

Tyre treads are designed to give good grip on wet roads, but in general wet grip decreases as tyre tread pattern wears down or as the depth of water increases. Motorists should take this into consideration and reduce speed when it is wet.The legal minimum tread depth in Europe is 1.6mm throughout a continuous band comprising the central three-quarters of the breadth of tread and round the entire outer circumference of the tyre. However tyre wet grip deteriorates more rapidly in the second half of its tread life and stopping distances in wet weather can dramatically lengthen. It is therefore advisable consideration is given to replacing tyres well before they reach the legal minimum. Tyre industry experts recommend replacing tyres at a remaining tread depth of 3mm – especially if you are running on winter tyres.

Tyre repairs

Repairs to car tyres must only be carried out by a tyre specialist and in accordance with existing regulations (for example the current British Standard AU159). Permanent repairs can only be carried out following removal of the tyre from the wheel to allow a thorough inspection internally as well as externally to ensure there is no hidden damage which could result in a catastrophic failure.

To avoid such a hazard, neither externally applied plug repairs, nor liquid sealants may be considered as a permanent repair. Tyre manufacturers cannot be held responsible for problems resulting from their use.

For repairs to run flat tyres, consult the relevant tyre manufacturer.

- Read on . . .

-

Wheels and rims

It is essential the wheel size is an approved fitment for the tyre and vehicle concerned. Tyres must not be used on damaged, distorted or modified wheels since this could result in tyre damage, deflation and possible loss of control of the vehicle.

Removal and fitting of tyres

These operations should only be entrusted to a trained tyre specialist who has the necessary equipment and expertise. Inexpert fitting can result in injury and damage to tyres and wheels. Wheels should be balanced after tyres are fitted or replaced.

Other information

Driving over pot-holes, kerbs, speed humps etc even at low speed can result in the weakening or fracture of the tyre’s structure. It is dangerous to re-inflate a tyre which has been run flat or seriously under inflated and such tyres should be removed for complete examination by a tyre specialist.

Tyre manufacturers cannot be held responsible for problems arising from modifications to their products, or the use of sealants which they have not approved.

Tyre Ageing and Servicing

The tyre industry has long recognised the consumer’s role in the regular care and maintenance of their tyres. The point at which a tyre is replaced is a decision for which the owner of the tyre is responsible. The tyre owner should consider factors to include service conditions, maintenance history, storage conditions, visual inspections, and dynamic performance. The consumer should consult a tyre service professional with any questions about tyre service life. The following information and recommendations are made to aid in assessing the point of maximum service life.

- Read on . . .

- Tyres are designed and built to provide many thousands of kilometres (or miles) of excellent service. For maximum benefit, tyres must be maintained properly to avoid tyre damage and abuse that may result in tyre disablement. The service life of a tyre is a cumulative function of the storage, stowing, rotation and service conditions, which a tyre is subjected to throughout its life (load, speed, inflation pressure, road hazard injury, etc.). Since service conditions vary widely, accurately predicting the service life of any specific tyre in chronological time is not possible.

Tyres should be removed from service for numerous reasons, including tread worn down to minimum depth, damage or abuse (punctures, cuts, impacts, cracks, bulges, under inflation, overloading, etc). For these reasons tyres, including spares, must be inspected routinely, i.e., at least once a month. This routine inspection should occur whether or not the vehicle is equipped with a tyre pressure monitoring system (TPMS). Regular inspection becomes particularly important the longer a tyre is kept in service. If tyre damage is suspected or found, it is recommended that the consumer has the tyre inspected by a tyre service professional. Consumers should use this consultation to determine if the tyres can continue in service. It is recommended that spare tyres be inspected at the same time.

Consumers are strongly encouraged to be aware of their tyres’ visual condition, such as cracking/crazing of the tread/sidewall rubber. Also, they should be alert for any change in dynamic performance such as increased air loss, noise or vibration. Such changes could be an indicator that one or more of the tyres should be immediately removed from service to prevent a tyre disablement. Also, the consumer should be the first to recognize a severe in-service impact to a tyre and to ensure that the tyre is inspected immediately thereafter.Tyre storage, stowage and rotation are also important to the service life of the tyre.There is no known technical data that supports a specific tyre age for removal from service.

However, in the interests of safety a number of vehicle and tyre manufacturers recommend that tyres (including spare tyres) that were manufactured more than a certain number of years previously be replaced with new tyres, even when they appear to be usable from their external appearance and the tread may not have reached the minimum wear out depth. It is recommended that any such instruction be followed. Consumers should note that most tyres would have to be removed for tread wear-out or other causes before any prescribed age is reached. A stated removal period in no way reduces the consumer’s responsibility to replace tyres as needed.

The chronological age of any tyre can be found on the tyre sidewall by examining the characters following the symbol “DOT”.

For tyres manufactured after the year 1999, the last four numbers identify the date of manufacture of the tyre to the nearest week. The first two of these four numbers identify the week of manufacture (which range from “01” to “52”). The last two numbers identify the year of manufacture (e.g., a tyre with the information “DOT XXXXXX2713” was manufactured in the 27th week of 2013).